FRP Composition & Strengths

FRP products used for structural reinforcement and strengthening have continuous fibers that run in a unidirectional pattern. They are pultruded or "prepreg" products such as reinforcing bars (rebar), plates, strips, and nets, or they can be dry fiber systems that are wetted with an appropriate matrix in the field such as tow sheets.

Composition

A few industry terms need to be explained: Pultrusion is the process where (usually) fiber tows are “pulled through a resin bath to wet-out the fibers, then drawn through a forming block that sets the shape of the composite and removes excess resin, and through a heated steel die to cure the resin.”[4] A cutoff saw is used to cut the solid FRP to length. A fiber tow (or roving) is a group of filaments gathered together without twisting. It is common for fiber tows used in FRP reinforcements to include up to 60,000 filaments per tow. The industry calls a carbon fiber grouping a "tow" and glass, aramid, and basalt fiber groupings a "roving." A tow sheet is a fabric in which tows arranged in the longitudinal (0 degree) direction of a fabric are held together by weaving a cheap, low strength fiber such as polypropylene in the transverse (90 degree) direction.

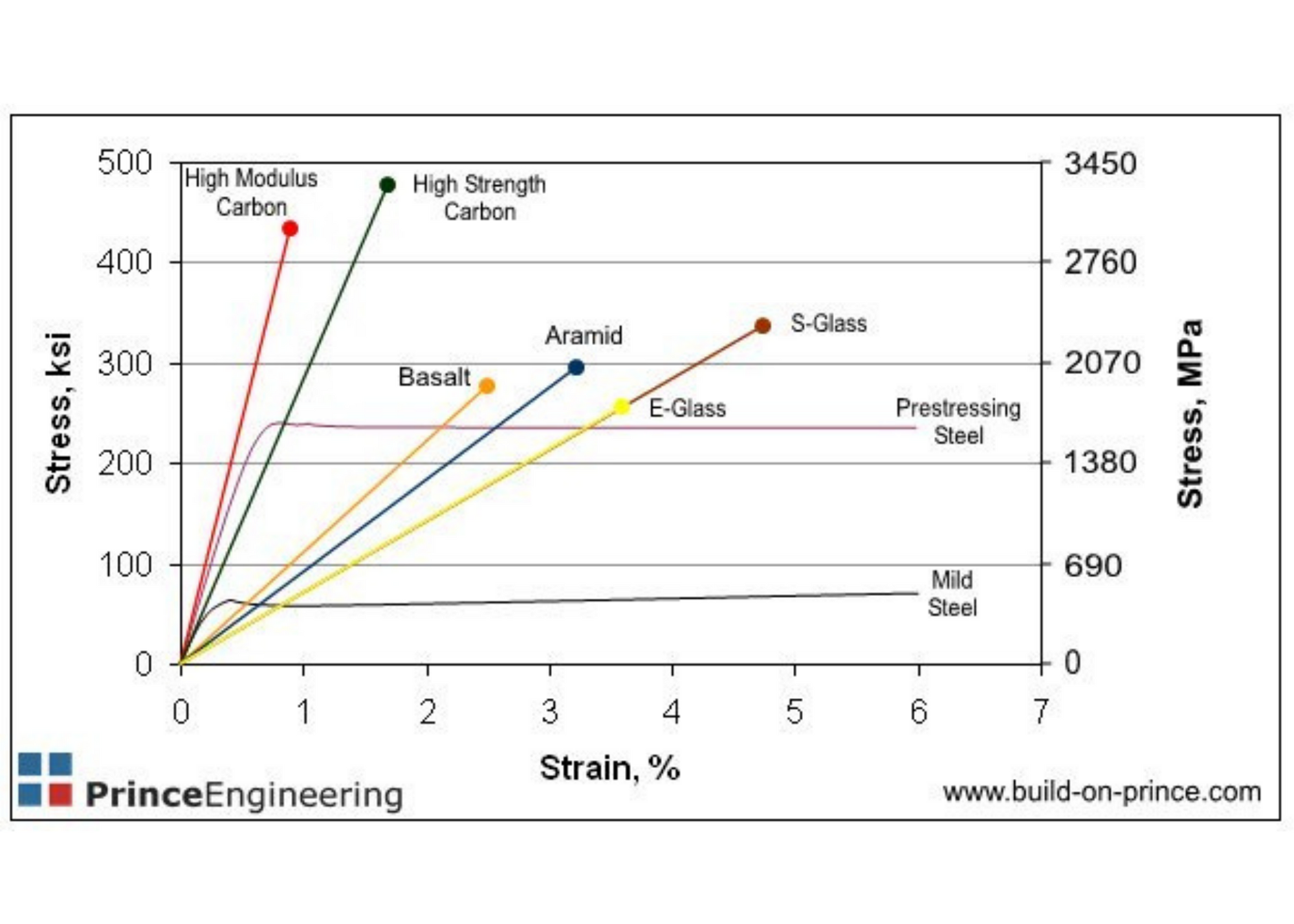

Typical strengths

E-glass fiber reinforced polymer (GFRP) has the lowest cost of all structural FRPs and is therefore the most utilized.Basalt fiber reinforced polymer (BFRP) has a higher cost due to a lack of manufacturer capacity, but with somewhat better strengths than GFRP, resistance to alkalies, and a nearly unlimited resource, its cost is sure to go down.Aramid fiber reinforced polymer (AFRP) is not as common a structural reinforcement due to the fibers' low compressive strength perpendicular to the fiber direction and higher cost. It is this feature, though, that makes aramid fiber the choice of ballistic resistant textiles because the fibers absorb impact very well.Carbon fiber reinforced polymer (CFRP) has the highest strength of FRP materials and also the greatest range of strengths. The range is due to the carbon source and manufacturing methods. CFRP is most resistant to creep rupture and fatigue failure than the other FRPs. Its higher cost is offset by its high strength and high resistance to cyclic and fatigue failures.

|

Internal Reinforcement for New Structures FRPs used as structural reinforcement are used in a wide variety of applications. As internal reinforcement, structural FRPs are produced in the form of bars (rebar), dowels, prestressing, and post-tensioning tendons. Externally bonded or near-surface-mounted FRPs are generally used for structural strengthening and repair of concrete, masonry, timber, and steel structures. FRP used as internal reinforcement are used in roads, bridges, slopes, tunnels, and marine environments. Because they are magnetically transparent, FRP reinforcements are used in hospitals where medical scanning equipment such as magnetic resonance imaging is used, in mag-lev railway ties and structures, and in bases of large electric motors. |

External Strengthening for Existing Structures Structural strengthening with externally bonded FRP reinforcement, especially with high specific strength carbon FRP, has been accepted by codes for seismic upgrades of structures for a number of years. The axial and eccentric loading of columns can be increased by wrapping columns with FRP reinforcements.For flexural strengthening, FRP reinforcement products such as tow sheets, plates, and bars are bonded to the tension side of a concrete, masonry, or timber substrate with a (usually) epoxy resin. Strengthening of structural flexural members have seen increased load bearing capacity of up to 40 percent.For shear strengthening, FRP reinforcements are bonded to the exterior of beams in a vertical U-shape configuration as an external stirrup. Shear strengthening of walls, such as unreinforced masonry walls and under-reinforced concrete walls, can be accomplished by bonding FRPs to one or both sides on the wall in either a vertical, horizontal, or X-pattern. |

Note: This website is about FRPpro, a software tool coming soon to assist engineers with the design of FRP reinforced concrete. Until then, we have included some basic information about FRPs. More information can be found on our engineering website.